Abstract:

Screw air compressor is an important part in factory automation industry, in the process of automated production line, compressed air is generally used as power source, for driving the pneumatic pumps, cylinders, pneumatic tools, and so on. Currently on the market customers adopt VFD to drive compressor motor, but also need the external controller to control the solenoid valve, cooling fan, and also need to use the DC power adaptor to provide the control power. This article will introduce a new solution for air compressor.

Keywords: GD300-21, screw air compressor, dual-VFD

1.Introduction:

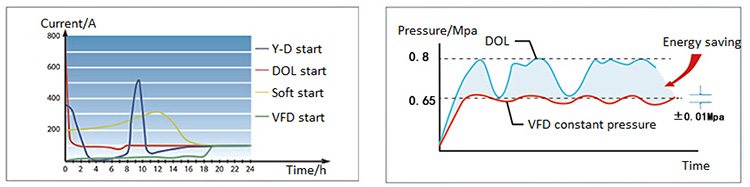

In the current market, most of air compressor solutions adopt VFD to drive compressor, compared with the old DOL start mode, the VFD aim compressor solution can save energy and cost about 20~40%.

Photo-1: Air compressor solution comparison

INVT GD300-21 a new dual-VFD air compressor solution, not only main compressor motor is variable frequency, but also the cooling fan is driven by VFD, and support to provide 220/110V AC control power.

2.Screw air compressor principle:

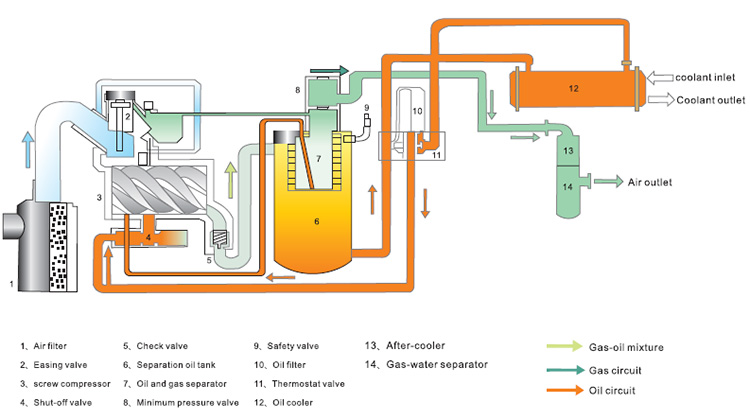

Screw air compressor principle is as following photo-2, includes air process and oil process.

Photo-2: Screw air compressor principle

a.When the input solenoid valve is open, ambient air gets sucked in throught the air filter, into the screw head.

b.Screw compresses the air by reducing the free space between each blade, the oil is injected in the compression chamber, to cool down and lubricate he element.

c.The heated oil-injected compressed air, passes through the non-return valve into the oil and gas separator tank.

d.In the separator, most of the oil, which was injected in the compression chamber, separated from the compressed air, and be collected to be re-used.

e.Once the pressure in the oil and gas separator reach the required pressure, the valve opens and allow hot air to flow into the aftercooler.

f.After the cooler, air is cooled down and exhaust to outlet, and oil is back to piple.

3.Frequency conversion air compressor

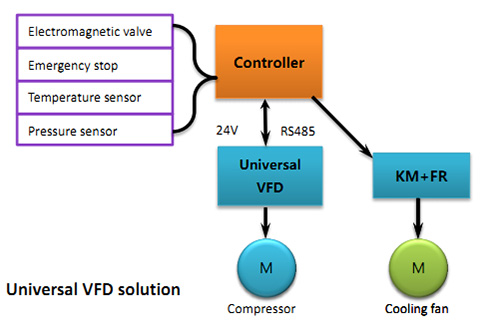

In the market, the normal frequency conversion air compressor solution is as photo-3, all the external signal are connected to controller, VFD is only for driving the main motor, cooling fan is start directly on line.

Photo-3: Universal VFD solution for air compressor

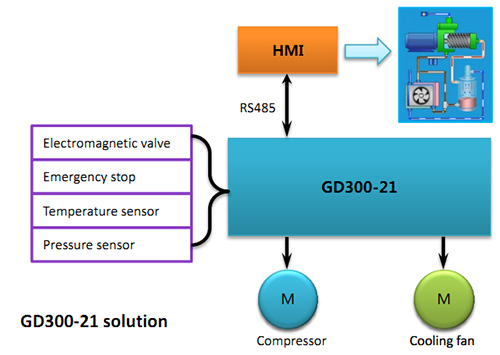

GD300-21 dual variable frequency drive integrated machine is special designed for air compressor, built-in all necessary function, not need external controller, just adopt HMI to monitor all running status and settings.

Photo-4: GD300-21 VFD solution for air compressor

4.Characteristics and advantages of GD300-21

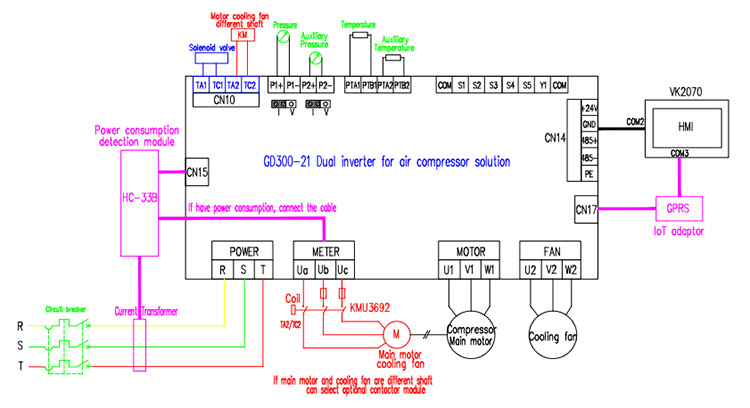

GD300-21 principle is as following photo, all compressor signals are connected to VFD, the advantages are:

Photo-5: GD300-21 principle

4.1 Dual frequency conversion: both compressor main motor and cooling fan are driven by VFD, with dual PID control, save more energy.

4.2 Built-in transformer: GD300-21 series are integrated with internal 30W 380 to 220/110Vac transformer, the AC control power can drive the solenoid valve and contactor directly by relays, no needs to add external transformer.

4.3 24V DC power: GD300-21 series come standard with internal large power 24W DC24V power supply, customer don’t need to add external 24V power.

4.4 Multi-function interface: Input terminals can connect the main and auxiliary pressure sensor, main temperature and auxiliary temperature sensor.

4.5 Friendly HMI: HMI can set and monitor the compressor parameters.

4.6 IOT: with the optional IOT adaptor, customers can remote control and monitor air compressor by mobile APP and website.

5.Typical application:

One customer adopts 45kW GD300-21 to replace old universal VFD.

6.Summary

After adopt the new GD300-21 replaced old universal inverter, customer don’t need to add more controller, transformer, and other electrical parts, only GD300-21 air compressor drive and HMI is enough for all configuration, reduced the electrical parts cost. With dual PID and dual frequency output, the new GD300-21 solution saved more energy compared with old solution.

References:

1.GD300-21 operation manual, Shenzhen INVT Electric Co., Ltd

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.