1. Preface

The bridge crane of rolling mill plant generally includes five major institutions: the main lift, deputy lift, cart, the main car, deputy car body. As the crane's bit load characteristics have more stringent safety requirements, the large inertia, short-term work, frequent starting brake operation of agencies has more harsh requirements to the speed adjusting program, Over the past decade, the mature of direct torque control theory and the successful manufacture of high-power vector inverter result in the successful application of frequency control technology in the crane. This paper describes the application of INVT CHV190 series inverter in the steel plant 125 / 32t tons metallurgical crane.

2. Profile of metallurgical crane system

The bridge crane main hook loads 125 tons, the vice hook loads 32 tons, with the four beams up and down car structure.

The main hoist part includes two sets 55kW motors, a reducer; each motor has two brakes, the brake in the form of hydraulic push rod; the main hoisting mechanism reducer is the planetary reducer, two motors output to reducer, through the reducer to control two sets steel wire rope reels, each reel is installed with two wire ropes, a total of four, through the four wire ropes to drive the following hook. Auxiliary lift is a 55kW motor drive, utilizing two hydraulic putter reducers to brake.

The main car part includes the two 15kW motors drive the reducer on both sides to drive the wheel, braking through a brake of each motor. Sub-car running motor is a 7.5kW motor drive a reducer to drive the wheel on both sides, and braking through a brake. Part of the cart includes four corners, four sets 30kW motors drive four reducers to drive the various parts of the wheel to work, each motor contains a brake.

3. Introduction of INVT CHV-190 series lifting special inverter

1. Main function brief

CHV190 crane special inverter is a high-performance vector vfd drive designed by INVT for the lifting industry. It is used for the AC stepless speed regulation of lifting, pitching, luffing, cart, trolley, turning and grazing of various cranes. The main features and features are as follows:

(1) Brake logic control and monitoring, pre-excitation and start the pre-torque compensation

Accurate brake opening and closing control timing, through the brake real-time state feedback and start the pre-torque compensation to ensure the safety and reliability of control.

Pre-excitation function directly conducts DC excitation to motor before the start to ensure that the motor can quickly provide the starting torque, and adjusting the excitation time to match the time of motor start and the mechanical brake release to avoid the "glid-hook" phenomenon.

(2) Light load speed upgrading (electronic vice hook) and loose rope detection

Crane with empty hook or light load can achieve 2 times operation speed and improve handling efficiency. The light load speed upgrading function is mainly used for hoisting crane with high lifting height: the speed of the hoisting mechanism is increased automatically when the hoisting mechanism is running with empty load, which can shorten the time to improve the loading and unloading efficiency. Under the heavey load, the speed is reduced to ensure the safety of equipment and person.

The inverter judges the load according to the average current value in a period after starting:

The inverter automatically reduces the output frequency when the load is heavy. When the load is light, the inverter will automatically increase the output frequency. The loose rope detection function prevents unsafe operation caused by malfunction of the light load speed upgrading function when the crane rope is loose.

(3) Control circuit power and main circuit power separately to improve the safety of user debugging, and easy to fault diagnosis and maintenance.

(4) Master and slave control power balance and speed synchronization technology

When the two large power motors are ridigly connected by the reducer to drive a hoisting mechanism, the master-slave control power balance function ensures uniform output of two motors. When the double lift mechanism hoists a heavy object, the master-slave speed synchronization function ensures the synchronization hoisting of two lifting mechanisms and ensure the safety.

(5) Second motor control and switching function

A inverter can automatically store two sets of motor parameters through the parameters self-learning, and achieve the high-performance vector control to two group motors through the switch command; it’s convenient for the control of electrical drive system and can reduce user costs.

(6) At the same time, support PROFIBUS-DP and MODBUS, INTERNET various communication protocols, achieving multiple communication connection between inverter and PLC.

(7) Dangerous speed monitoring, fast stop and overspeed protection

The inverter monitors the running speed of motor in a real-time, when the motor speed is greater than the set maximum allowable speed or speed deviation value, the inverter sends out the fault alarm and stops the output immediately, and the mechanical brake moves to keep the crane in a safe state.

The quick stop function gives user the following three options:

Mode1: parking of electric brake; mode 2: electric brake plus mechanical brake parking; mode 3: mechanical brake parking.

(8) Crane operating mode

According to the different operating modes of crane, the following operating modes are provided: joystick mode, remote control mode, electric potentiometer mode, graded joystick reference mode, hierarchical remote given mode, communication reference mode and so on.

2. Application scope

CHV190 crane dedicated vector drive has excellent torque control performance, is widely used in theAC stepless speed regulation of lifting, changing, carts, cars, rotary, grappling and other institutions of shore container cranes (STS), rail container gantry cranes (RMG), tire container gantry cranes (RTG), portal cranes, shipbuilding gantry cranes, loading machines, unloading machines, tipping machines, stacker and other types of port machinery, and all kinds of ordinary bridge, portal, tower cranes and girder crane, bridge-erecting crane and other lifting machinery.

4. Metallurgical crane system control scheme

The cart and car system all uses CHV190 inverter producted by Shenzhen INVT electric Co, Ltd., the main and vice lifting mechanism adopt stator voltage regulator technology and rotor series resistance speed mode. The system is configured as follows: The cart traveler adopts two inverters to drive the two motors with same beam. The master and slave application softwares are used to ensure the speed synchronization and load balance of two motors to prevent the twisting and gnawing of the girders.

Car inverter adopts an inverter; The main and vice hoisting mechanism respectively adopt stator voltage regulator speed control device and rotor series resistance speed control mode. The whole system uses energy-saving braking mode to continuously regenerate energy in the form of thermal energy consumption to achieve braking.

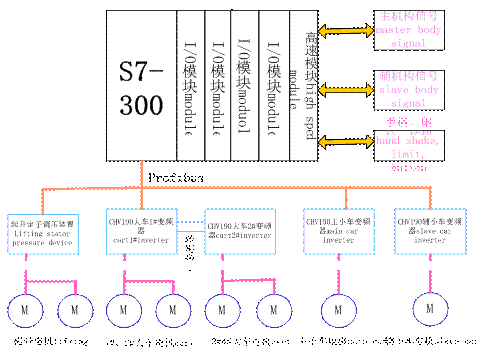

All the inverter are configured with a variety of standard field bus interface, electronic control system diagram shown in Figure 1.

The system uses Siemens S7-300 as the core controller, adopts the industrial control field bus to connect the PLC, remote I/O, mechanism inverter and the touch screen to reduce the cable investment, wiring and maintenance workload, and trouble points.

Remote I / O and touch screen are installed in the driver's cab. They accept the instructions of operator to display various operating conditions of the system to facilitate the monitoring and operating of operator and the fault diagnosis and maintenance of maintenaner. PLC receives the status information, inverter and other status information of scene detection device to control the system operation.

Figure 1 Schematic diagram of the electronic control system

Figure 2 bridge crane on-site operational picture

Figure 3 inverterdiagram of electronic control system

5. Conclusion

The system uses Siemens S7-300 PLC as the core controller, and forms a high reliability system combined with CHV-190-4 series lifting special inverter, which has fully meeted the requirements of production process and mechanical equipment, displayed the superior performance and high reliability of the inverter, and gained the user's praise. After a successful debugging, the whole equipment of the metallurgical crane is running well, and can fully meet customer demand for production. At present, the system runs well and stable in the actual working environment.

References

1. “CHV190 series crane dedicated inverter manual”

2. “DBU brake unit instruction manual”

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.