Summary: In this case,through introducing INVT GD5000 medium voltage VFD applied to Vent fan in gold mine in the South Africa to illustrate economy and characteristics of variable frequency drive. Especially significant energy saving.

Keywords: GD5000 medium voltage drive, gold mine, vent fan, energy saving.

1.Project introduction and analysis

Harmony Doornkop gold mine is in the Gauteng province, South Africa. This plant belongs to Harmony Gold mining. The Harmony Gold is the first largest gold mining company in South Africa.

There is one vent fan used baffle to control air speed and air flow. This is an old technology speed control method, through this way has below disadvantages:

1)Narrow adjusted speed range.

Due to baffle control method can’t be elaboration and sensitive, so the system adjusted speed range is narrow.

2)High power loss.

Because of baffle control method is an old and outmoded speed control technology, there is much power consumption during speed adjust period.

So the customer decided to use VFD instead of above old speed control method.

2.System Configuration

2.1 Motor introduction.

Detailed motor parameters are list as follow:

Table 1.Vent fan motor Parameters

| Motor Model | Power | Rated Voltage | Rated Current | Rated Speed | Power Factor | Load Type |

| / | 1500KW | 6600V | 159A | 735RPM | / | Vent fan |

Figure 1.The vent fan motor

2.2 System solution.

Based on INVT experience on mining industry VFD renovation project, INVT can supply whole solution for the customer.

According to customer demand, the medium voltage drive consists of manual bypass cabinet, transformer cabinet, power cell cabinet and control cabinet. The GD5000 VFD has function of local/remote button and emergency stop button on control cabinet.

INVT suggest VFD solution:

Table 2.VFD for vent fan

| VFD Model | Power | Rated Voltage | Rated Current | Quantity |

| GD5000-A2000-6.6-S | 1600kw | 6.6KV | 175A | 1 |

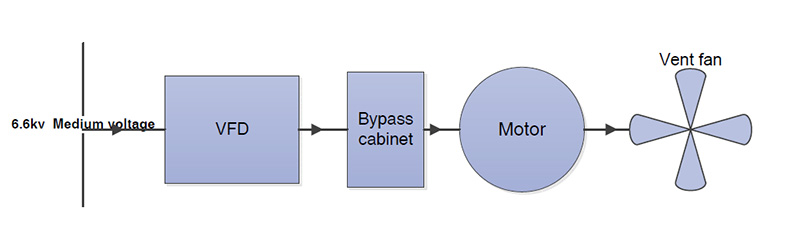

Main systme diagram:

Figure 2.The system diagram

Figure3. The vent fan VFD and motor

3.Application and Advantage

After using VFD, there are some major advantages as follow:

1.Energy saving.

The vent fan and it system is running at optimal situation and can save energy.

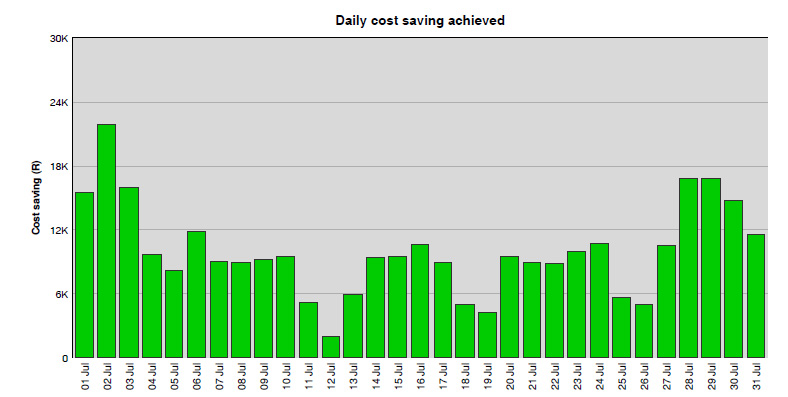

Below graph is actual running data from site during VFD running one month (July/2020):

Figure4. At July/2020 daily cost saving

From the site real running situation during one month, the energy saving ratio is about 21.6%.

Below data is collected from site VFD running one month.

| Date | Impact(kW) | Cost saving(R) | Energy cost(R) | Energy saving(kWh) | Energy usage(kWh) |

| Total | 309288 | 1372535 | 217501.70 | 1004936.80 |

The energy saving is: (217,501.7)/(1,004,936.8)=21.6%

2.Wide range speed adjusted.

Because VFD is a step-less speed regulation, the vent fan can be run smoothly with wide speed range. It means that the speed adjusted can be elaboration and sensitive.

3.Increase grid line power factor.

The grid line power factor is over 0.97. It can increase efficiency of the grid power.

4.Perfect output waveform.

Output waveform is perfect, less than 2% of distortion.

5.Prolong motor working life time.

VFD can keep motor running at optimal situation.

4.Conclusion

Compared with old technology, the VFD driven method has many advantages. Especially significant energy saving. The energy saving ratio can reach 21.6%. The transformational VFD system works very well, customers are satisfied with INVT solution and INVT VFD met with customer’s requirements.

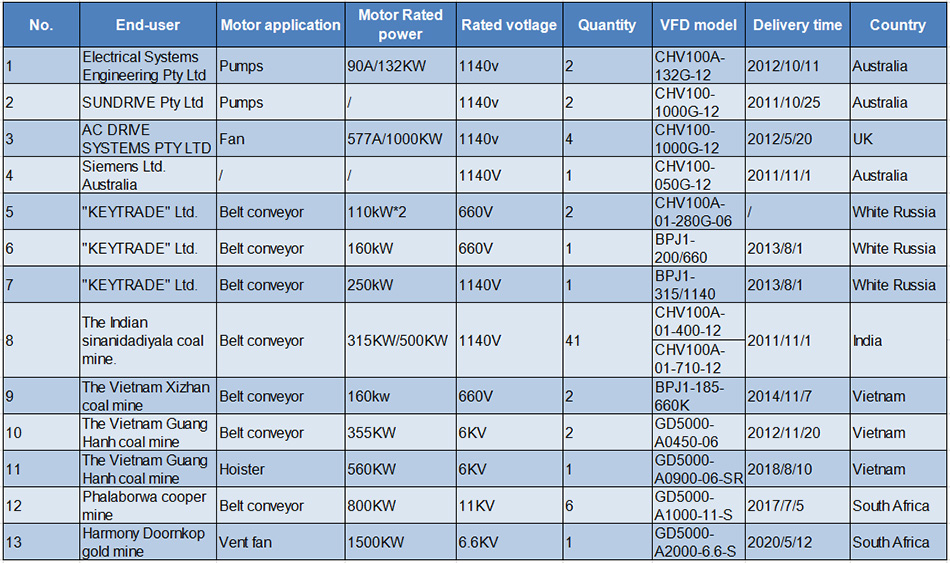

5.INVT VFD Reference in mine industry

Below table is the part of reference INVT VFD in mine industry at overseas market:

References

[1] GD5000 Series Medium-voltage Variable Frequency Speed Control System Manual. Shenzhen INVT Electric CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.