Background

With the rapid advancement of technology, product iteration cycles are becoming increasingly shorter. Traditional manual production lines can no longer keep up with the fast-changing demands of modern manufacturing. Automated production lines have emerged as the preferred choice for the industry, offering significant advantages in improving efficiency, ensuring product quality and consistency, and reducing costs. Among the key components of such lines, loading and unloading robots play a crucial role in linking processes. Their performance and stability directly impact the overall efficiency of the production line.

Customer requirements

Amid increasingly fierce market competition, the customer has raised higher expectations for the performance of the automated production line:

• Resolve inconsistent material placement: The existing robot arm places materials with uneven spacing, which can lead to items falling and disrupt production efficiency.

• Increase production speed: The customer aims to further accelerate the production process to meet the growing demand for faster delivery.

INVT solution

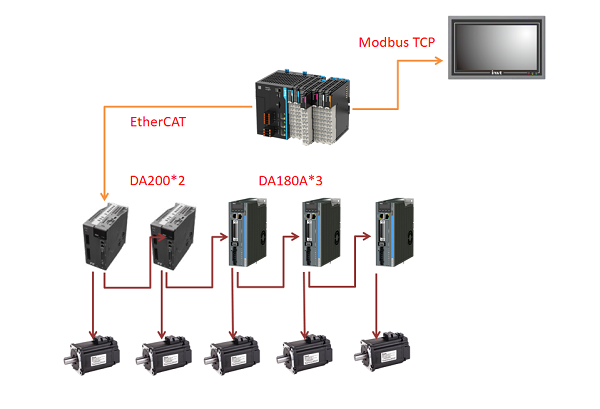

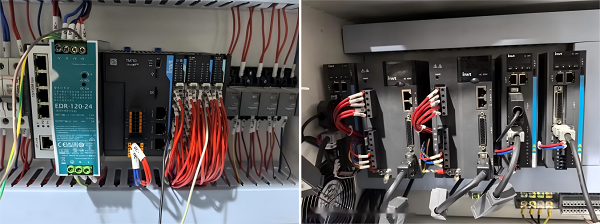

To meet the customer's urgent needs, INVT introduced a fully EtherCAT-based control system built on the VS-Q series HMI, TM700 series PLC, DA200 servo, and DA180 servo. The system utilizes electronic cam technology to achieve precise master-slave axis control. Combined with advanced algorithmic compensation and optimized motion logic, it significantly improves material placement accuracy and production speed—fulfilling demands for diversified production, rapid delivery, and cost reduction.

Solution advantages

1. High-precision material handling: Compared with traditional solutions, the INVT system ensures accurate and reliable material pick-and-place operations across a wide speed range—from low speeds of 2 m/min to high speeds of 20 m/min. The system runs smoothly and delivers outstanding performance.

2. Strong compatibility: Featuring a full cam-based system and automatic compensation algorithms, the entire machine cycle can automatically adjust to match the production line speed. There is no need for the customer to manually adjust the speed of each axis, significantly reducing setup time.

Customer benefits

1. Improved product quality: The placement gap deviation has been reduced from a maximum unevenness of 1.5 mm to a consistent 0.5 mm, effectively preventing material drops and enhancing overall product quality.

2. Increased production speed: Maximum operating speed has been raised from 18 m/min to 20 m/min, further improving production efficiency.

3. Efficient commissioning: Automatic adaptation to both high and low speeds eliminates the need for group-specific parameter adjustments. Servo parameters can be easily configured via the upper-level software, with support for batch import/export—greatly accelerating the setup process.

4. Safe and reliable operation: In the event of manual operation errors, the system automatically moves the Y and Z axes to a safe standby position until the fault is cleared. In case of axis alarms or other issues, the entire system halts immediately, effectively preventing equipment collisions and other safety risks.

Conclusion

With its broad product portfolio, INVT has achieved remarkable success across a wide range of industries in the field of automation. The TM700 has effectively addressed key challenges in automated production lines, including inconsistent material placement and limitations in production speed. With advantages such as precise handling, strong compatibility, efficient commissioning, and reliable safety features, it has delivered significant productivity gains for customers. Looking ahead, INVT will continue to invest in R&D, focusing on technological innovation and product upgrades to deliver even more efficient, high-quality automation solutions—driving the intelligent transformation of the manufacturing industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.