Abstract: Global Mesindo offices are in Jakarta and Surabaya – Indonesia and have distributed any plastic machineries since 1999. It mainly sells Japanese, Taiwanese and Chinese plastic machineries and auxiliaries such as injection molding, blow molding, pelletizing line, extrusion blow, PET blow molding, inject blow molding, robot, mixer, crusher, dryer loader, MTC and etc. Besides new machines, it also sells used (reconditioned) Japanese injection molding, blow molding and inject-blow molding machines such as Toshiba, Nissei, JSW, Niigata, Kawaguchi, Mitshubishi, Tahara, Placo, AOKI and etc. With INVT hydraulic servo system, the precision is higher, energy-saving effect more apparent.

Keywords: Injection molding machine, Hydraulic Servo,MH500.

1. Project introduction

JSW - J220E injection molding machine hydraulic servo energy-saving renovation:

| Original Configuration | |||

| Motor rated speed | 1180 rpm | ||

| Pump type | SQP321-30-14-7-86ACD2-18 | Pump delivery | 95+43.3+22.9(ml/r) |

| System flow | 190 L/min | System pressure | 140 bar |

| Servo Hydraulic | |||

| Sumitomo pump | QT6N-100 | Drive type | KT-CT-3502-A-1 |

| Servo motor type | K187F18C25P | ||

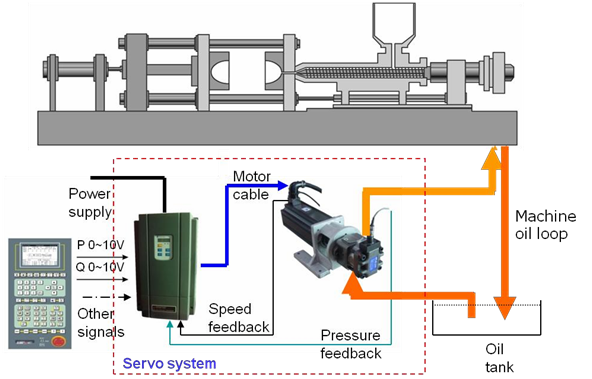

2.System schematic diagram:

3. Project features and advantages

1) Power saving

Remarkable power saving ability, high advanced motor control automatically adapt to plastic process, compared to induction motor, servo saving power cost about 70%.

2) More accurate

With pressure and flow rate PID feedback system, the close loop system can be more accurate control process, raise plastic products and mold accuracy 2%.

3) High Efficiency

Servo has more than 3 times of sudden overload ability 2500 r/m speed, compare to normal induction motor, same condition reduce process time 15%

4) More working life

Servo system reduce impact, increase system working life time 20%

4.Typical application

Hydraulic servo installation drawing

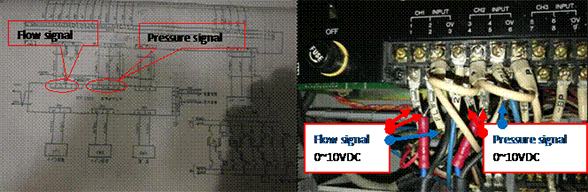

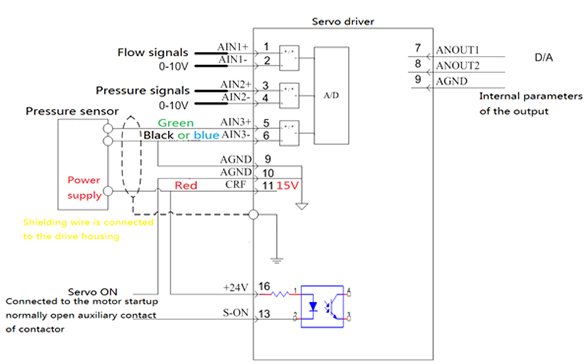

Pressure and flow rate for a given signal wiring diagram

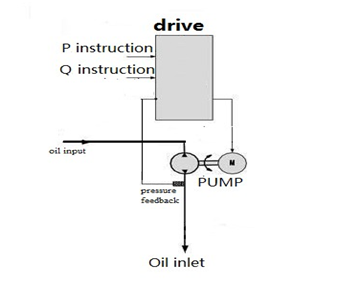

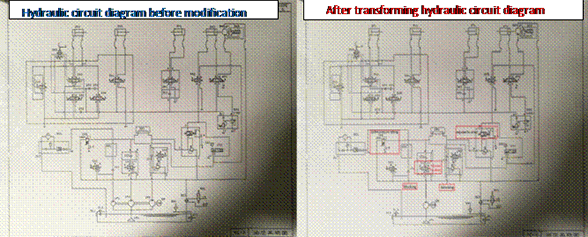

The hydraulic circuit principle diagram

The hydraulic circuit principle diagram

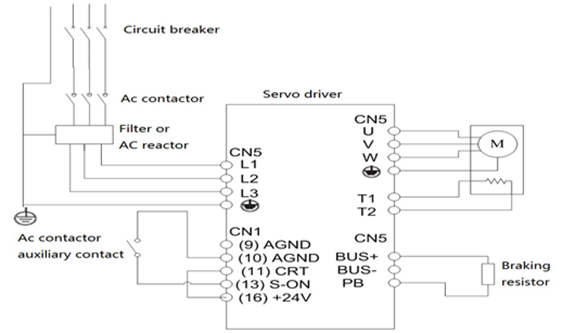

The wiring diagram:

Debugging and parameter Settings

1) According to the wiring diagram 4.1 connection cables;

2) Cooperate with computer injection molding machine, calibration of the hydraulic system of zero pressure, pressure on full scale, zero flow, flow full scale;

3) Test the machine pressure and machine movement;

4) Injection molding machine mold trial production.

5.Reference

MH500 Hydraulic servo system operation manual.

INVT Kinway servo application on injection molding machine.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.