Some agencies have predicted that about 54,000 oil wells will be drilled worldwide in 2021, an increase of 12% from 2020. It is expected that in 2022, the number of drilling will further increase, an increase of 19% from 2021, which is undoubtedly the dawn of a full recovery for the global drilling market that has suffered a huge blow in recent years.

Drilling "oil to electricity" has great potential

As the "leader" of oil and gas exploration and development, the obvious increase in the scale of drilling indicates that the workload of the oil industry will maintain rapid growth in the future.

In the past, diesel engine for the power driven drilling rig market holding is not low, and under the demand for carbon neutrality, with more environmental protection, energy saving, low noise motor drive way is gradually replacing the diesel engine as a power drive, and has strong development potential.

Customer demands

In the 4000m drilling rig project of a drilling company in the northern China, the on-site motor is 1000kW; the voltage is 10kV. Two motors through transmission device to provide power for drilling system.

The on-site motor will drive transmission device, the transmission device provides power for the mud pump and the winch, the winch drives hook and turntable, the switching of each driving mechanism is through the air source room to provide power, and then through air tire clutch to switch transmission device and motor, mud pump, winch.

The control room will adjust the motor speed according to the specific drilling depth and drilling process to meet the drilling process requirements.

lINVT’s solution

The original driving method at customer site is driven by an internal-combustion engine to provide power for the drilling rig. Now the customer replaces it with two motors to provide power for drilling rig through the power grid, realizing the conversion from oil drive to electric drive.

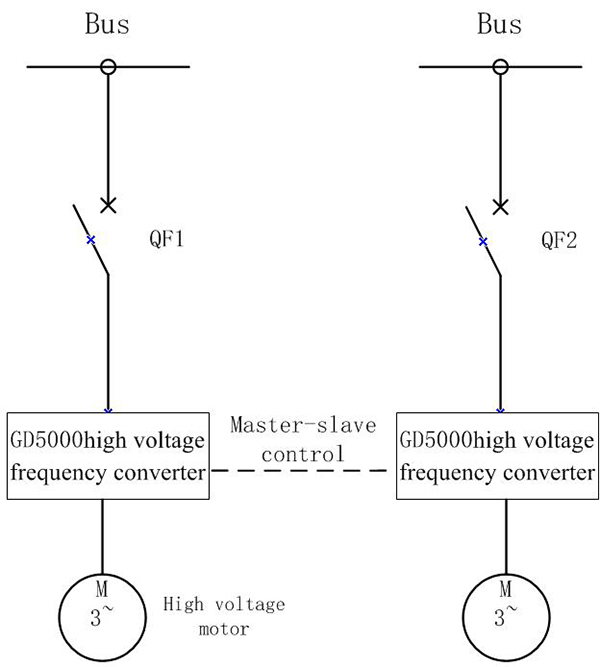

Two Goodrive5000 VFDs through master-slave communication connection, the host running speed mode, slave running torque mode, so as to ensure that the two units output same torque, the dynamic response of the two units is more coordinated, so that the system’s operation is more stable and reliable.

Features of the INVT solution

Goodrive5000 series medium voltage frequency converter speed regulation system is a new generation of high voltage (synchronous/ asynchronous motor) three-phase AC motor speed regulation and drive device independently developed and designed by INVT.

INVT Goodrive5000 series medium voltage frequency converter speed regulation system adopts multi-phase shifting multi-unit series sinusoidal pulse width modulation (SPWM) superimposed pressure technology, direct "high-high" type, and the power module is an AC-DC-AC voltage source inverter speed controller.

The use of INVT Goodrive5000 series medium voltage frequency converter electric drive replaces oil drive device has the following advantages:

1.Self-developed high-performance sensorless vector (asynchronous/synchronous motor) control technology with high accuracy and fast dynamic response.

2.Self-developed high performance speed sensorless vector control technology, high precision, fast dynamic response.

3.The efficiency of frequency converter is over 96%.

4.Master/slave control function which has achieved multi-motor simultaneous drive control.

5.Low harmonic device which is far below the national standard requirements of 4%.

6.High power factor, power factor 0.95 or more, no need to add compensation device.

7.The two motors on the site can run both the single-machine mode and the master-slave control mode, which is redundant with each other and is more safe and reliable.

8.The system is low noise, pollution-free, greener and environmentally friendly.

The customer benefit

According to the data that provided by the customer site:

In the case of motor drive,the daily power consumption is 18,000 kWh, according to 1.1 yuan / kWh, the daily cost is 19,800 yuan.

In the case of internal combustion engine drive, the daily oil consumption is about 4 to 5 tons. According to 7000yuan per ton, the daily cost is 28,000 to 35,000 yuan. In the case of completely using electricity, it can save about 10000 yuan a day, and the energy-saving effect is obvious.

It is shown by on-site application that INVT Goodrive5000 series high voltage frequency converter has stable operation, good response effect and the energy-saving effect is obvious, which is a good helper for oil to electricity conversion projects in the drilling industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.