Abstract: This paper has introduced the feature of oil drilling rig, INVT GD3000 series 3-level frequency drive, and the application on drillings rig in Russia.

Keywords: Oil & gas, drilling rig, frequency drive, 3-level, GD3000

1.Forewords

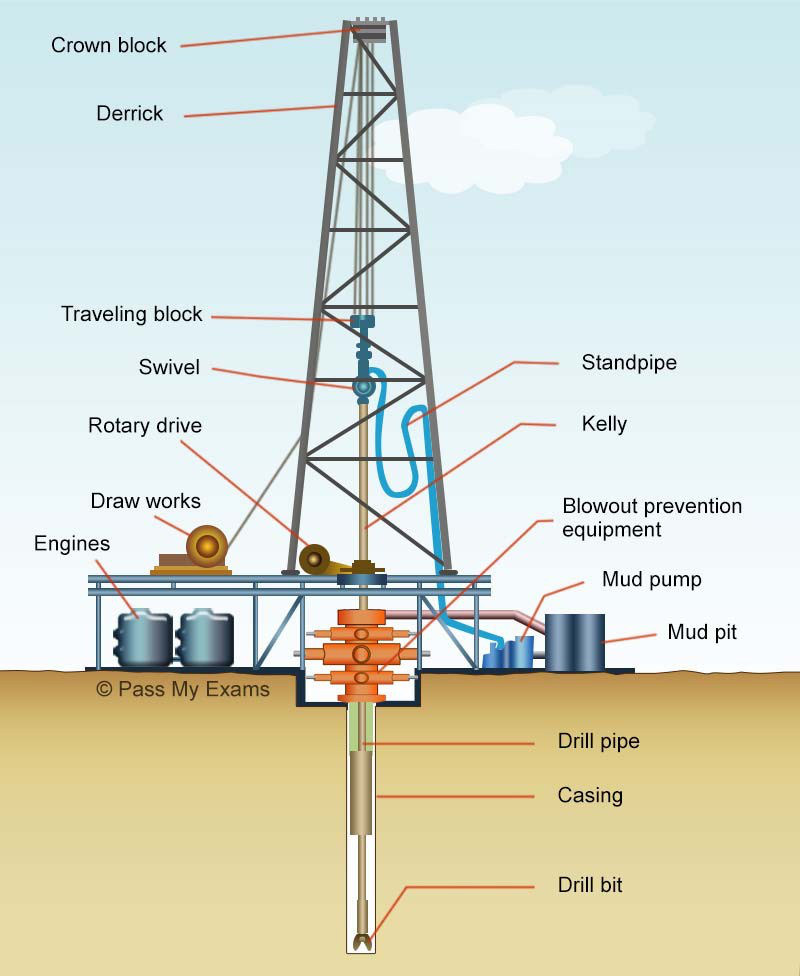

Oil drilling rigs are massive structures housing equipment used to drill oil wells, or natural gas extraction wells, which are capable of drilling through thousands of meters of the Earth's crust.

An oil drilling rig is mainly composed of three main transmission mechanisms, Rotary table, winch, and mud pump.

Rotary table: rotates the drill string along with the attached tools and bit.

Draw-works: to raise/lower the pipe, drill string and drill bit.

Mud pump: to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled.

These mechanisms are driven by common DC bus inverters. Usually an oil drilling rig operates 24h every day, it requires the inverters have the extremely high reliable performance.

Fig.1 Simple illustration of drilling rig[2]

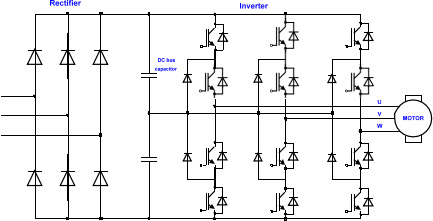

2.Project introduction

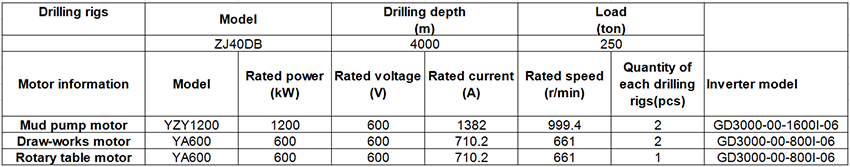

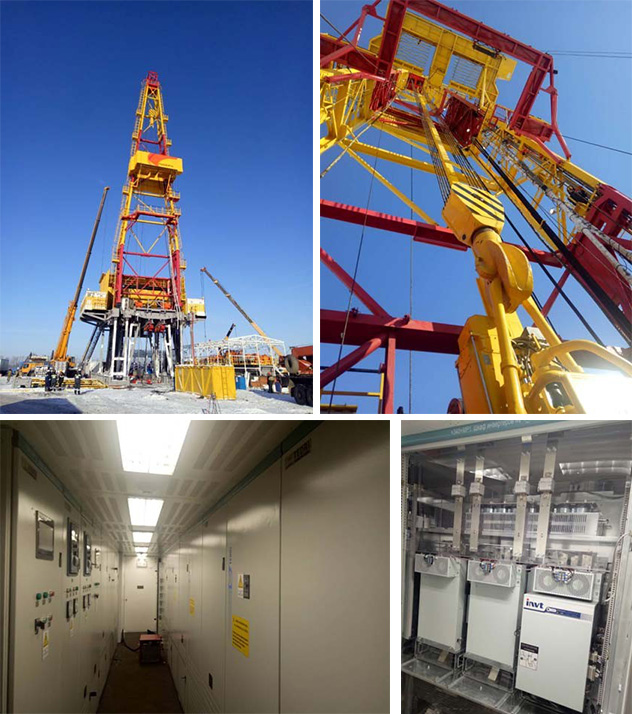

The project is located in Samara, Russia, there are totally 11 sets of drilling rigs.

The electrical control part is mainly composed of a series of containers called "e-house", including VFD (Variable Frequency Drive), MCC (Motor Control Center), HVR high-voltage room and driller's room.

One VFD room adopts 7 sets of common DC bus GD3000 inverters to drive the winch motors, mud pump motors and rotary table motor.

System one-line diagram:

Fig.2 System one-line diagram

3.Advantage

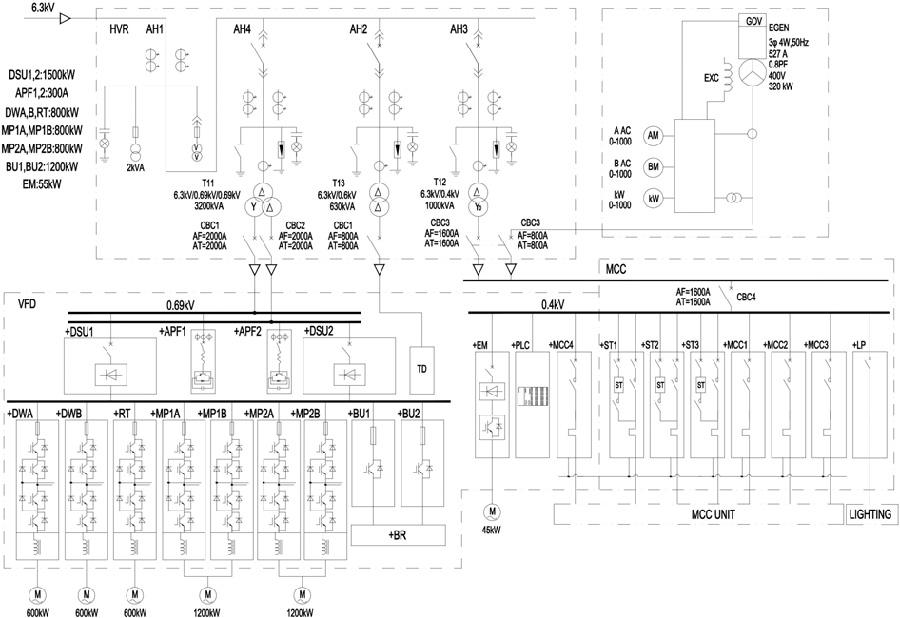

Fig.3 GD3000 3-level inverter diagram

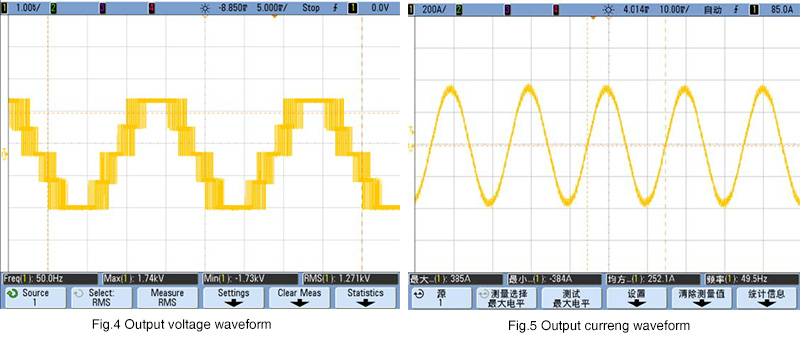

1)Output waveform is better than 2-level inverter, more similar to sine wave

2)Low dU/dt, low peak voltage to motor, reduce damage to motor insulation

3)Lower harmonic under same carrier frequency, THDi<5%, THDu <3%

4)High overload capacity (150% 1min, 180% 10sec), and big torque at low frequency

5)Standard field bus Profibus-DP and ProfiNet, compatible with the mainstream controller

6)Multiple protection functions, ensure system reliability

7)Modular design, easy maintenance

4.Site photos

Fig.6 Field site photos

5.Conclusion

Oil drilling rig is the highest level of application in the oil industry. Rig equipment generally faces complex and harsh external working environment, and has a high rigid demand for advanced equipment and reliability. With excellent product performance, reliable product quality and good market reputation, INVT products have been successfully applied in the core equipment of oil drilling rigs, breaking through the long-term monopoly of international first-tier brands.

Reference

[1]Shenzhen Invt Electric Co., Ltd. < Goodrive3000 Series Inverter Operation Manual >

[2]www.passmyexams.co.uk . < Drilling for Crude Oil - The Drilling Rig>

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.