Before the industrial revolution in the 18th century, Britain was ready for the industrial revolution, both in economic terms and in science and technology. As long as there was a spark, it could ignite the blazing fire of the industrial revolution. The first spark came from the textile industry. For centuries, Britain has been famous for woolen goods, but pure cotton is produced only by Indians. In order to get rid of the shackles of commercial competition, people invented the "flying shuttle". This is the first machine to increase the production capacity of hand-woven fabrics, that is, traditional looms.

The traditional loom, also known as the "pedal loom," has a simple tool, complex operation, and particularly loud noise. It consists mainly of "nose", "hang" and "loom". In weaving, the shuttle passes through the middle of the two layers of warp, leading the weft to intersect with the warp, and then squeezing through the loom to form the cloth. Such a loom is bad for both eyes and hands.

With the development of science and technology and the progress of society, the textile industry has also developed by leaps and bounds, and the weaving machinery has been continuously improved and upgraded.

Let's take a look at INVT's solution for a new water jet loom:

The working principle of New Loom

The new loom has made considerable improvement in technology. First, it has replaced the shuttle with water spray, greatly freeing both hands. Such looms are also called "water jet looms", which consists of five auxiliary devices, such as opening, weft insertion, beating-up, warping and coiling, and related monitoring and controlling devices.

The new water jet looms with high efficiency have the following characteristics:

Support electronic let-off, electronic coiling, servo machine external roll function, to achieve high efficiency, smooth weaving and more weft dense selection, to meet the needs of personalized weaving;

Support electronic jacquard, electronic Dobby function to meet the needs of multi-variety switching;

Support inverter starts with high torque, realize the different speed adjustment, and enhance the weaving efficiency;

Support automatic weft finding function.

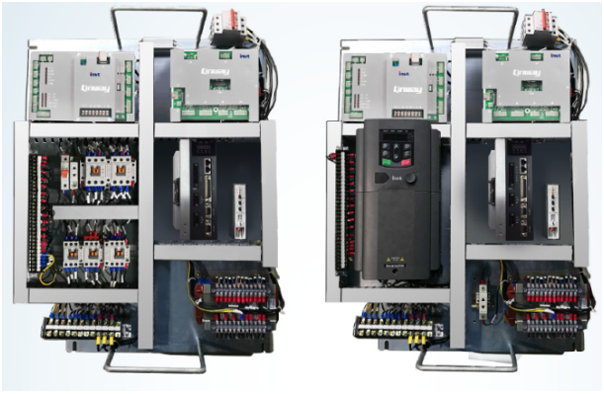

INVT WS 900 water jet loom solution

It is not enough to optimize looms. Through the science popularization above, we know that the quality of cloth is affected by tension and beating torque; the higher the torque, the higher the quality of the first weft; the higher the consistency of the weft density and the more uniform the cloth surface.

In order to fully liberate both hands and ensure that beautiful cloth can be woven, a set of solutions tailored to the water jet loom came into being-INVT WS900 water jet loom electromechanical control system; this system

1. With real-time tension control and adaptive parameter correction of radius variation of warp axis, the loom runs more smoothly.

2. The integrated let-off and coiling algorithms have the function of automatically adjusting tension and compensating, effectively reducing the starting mark and improving the quality of cloth.

3, Support inverter starts with high torque, realize the torque of loom start super high rate, prevent stop gear and the weft of the first weft to relax.

4. No need to replace the pulley to meet the different weaving speed and slow speed inch speed, different spindle speed adapt to different yarn, easy to adjust, flexible application.

5, Integrated the pattern control of the weft storage device and power supply transformer, only need to match the weft storage head, support 2 sprays, 4 sprays.

The integrated loom controller, electronic take-up and let-off, spindle drive in one of the overall solution, in addition to strong compatibility, also have features like energy saving, automatic compensation for starting marks, stability, easy speed regulation, easy installation and maintenance, and so on.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev