Multi-drive system, referred to as "multi-drive", is relative to a single drive, which means that two or more motors run simultaneously on a single production line or a set of equipment.

With the accelerating pace of the modern industry, the scale of some enterprises and factories is increasing. which requires more and more transmission points of the motor to achieve complex processes, the importance of multi-drive system technology is increasingly prominent. It can realize the variable frequency control of multiple motors, which can meet various control requirements of on-site working conditions, and can also improve the production process and improve production efficiency.

Multi-drive System

01. Basic requirements for the safety of multi-drive systems

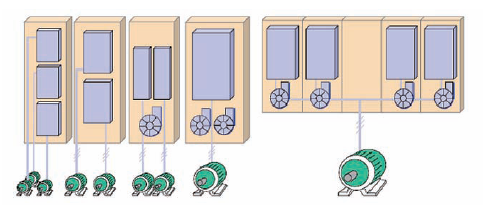

Multi-drive means that there are two or more inverters hanging under a rectifier, that is, the relation between rectifier and inverter is one-to-many. The most common DC bus drive system is a typical multi-drive system.

There are two main characteristics of the common DC bus: one is to simplify the structure of the system, to omit as much as possible, and the other is to make the best use of the material to save energy. Under the common DC bus, all the inverters do not work in the same state, there are electric and power generation, so the energy can flow inside the energy and realize energy saving. The key to the design of common DC bus is correct calculation, reasonable capacity selection of rectifier and inverter, and perfect protection of parallel connection and connection of the system. Otherwise, once there is a fault, especially prone to "domino"-type chain failure.

It can be seen that one of the basic requirements of multi-drive inverter control system is that individual failure will not affect other individuals. INVT Goodrive600 multi-drive inverter uses "DC fuses" to achieve this function. In the case of multi-motor transmission, when one inverter is damaged, the fuses ensure the safety of other inverters by fusing behavior. This technology is widely used because of its effectiveness.

02. Basic requirements for multi-drive inverter control system communication

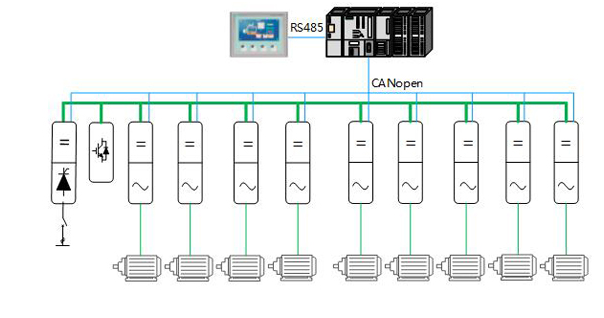

The synchronization technology of 100 megabits industrial Ethernet is the key technology in the multi-drive variable frequency technology. The synchronization method and synchronism performance can directly affect the number of the most expandable rectifier and inverter modules in the multi-drive frequency converter.

At present, there is some commonly used industrial bus like CANopen, PROFIBUS-DP, PROFINET, EtherCAT, MODBUS/TCP and so on.

One hundred megabits industrial Internet Ethercat synchronous communication technology is the best synchronization technology at present. MODBUS/TCP is more economical and is often used in situations where communication speeds are not high. These industrial buses have their own strengths and use different industrial buses under different operating conditions. Goodrive600 series inverter has designed many communication cards and mass production, including Profibus DP communication card, CANOpen communication card, DeviceNet communication card, Ethernet communication card, Ethercat communication card and so on. At the same time, it supports the Anybus-S series communication card and Anybus-CC series communication card of Swiss famous industrial communication company HMS, which can be compatible with all commonly used industrial buses and flexible set up the network, thus reducing the investment cost of the owner's equipment.

03. Basic requirements for Assembly of Control system of Multi-drive Inverter

Different from single drive inverter control system, multi-drive inverter control system is mainly used in metal processing, mechanical manufacturing, textile, small papermaking, automation production line and so on. Most of these industries use medium and small power inverters. Therefore, most of the multi-drive inverters in the market adopt the "book type" design, which can save space on the one hand and reduce the cost of system integration on the other.

With the development of industry, the function of the inverter is becoming more and more precise. If the multi-drive inverter can be made into a reference module, it wouldn’t be better we can define the functions we need. Based on this, Goodrive600 Series Inverter's original card expansion emerged. If you want to add a module when extending, you can just make the module connect with synchronous communication network cable in any position of the system. If you want to delete the module, you can just unplug the synchronous communication network cable to get rid of system. After the whole system is connected to the network, the control module can automatically identify the types of each module and the network topology, and the user can make the system run without any configuration. At the same time, the system can also do redundant design.

"Make all efforts to offer value-added products and services to strengthen client’s competitive advantages", INVT is adhering to such a mission, from security guarantee to self-defined product design breakthroughs, multi-drive inverter technology to a new level.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev