With the increase of human cost and the continuous improvement of quality and productivity requirements of processing enterprises, the demand for machine vision system to intervene in the production field to replace manual measurement and testing shows a rapid growth trend. In the precision electronics industry, the use of machine vision for product size measurement, appearance detection, alignment and other applications have been very mature. In some high-precision alignment applications, machine vision products measurement accuracy has greatly overloaded the resolution and precision of manual detection.

Whether you know it or not, machine vision is here! It has become an extension of the human eyes, helping us to see and analyze every nuance of the product more clearly and accurately, so as to realize more stable and intelligent production.

INVT are continually tapping into the needs of the industry demand, focusing on electronics manufacturing precision market and digging into industry technology and processes. Finally, it had a perfect fusion of solutions and products, solved the difficulties of the user, and launched the perfect solution of machine vision equipment from motion control to drive to the execution. This solution helps manufacturers improve product quality and production efficiency, increase equipment capacity, reduce labor costs and add their value. The following is INVT's visual inspection system application in a research institute.

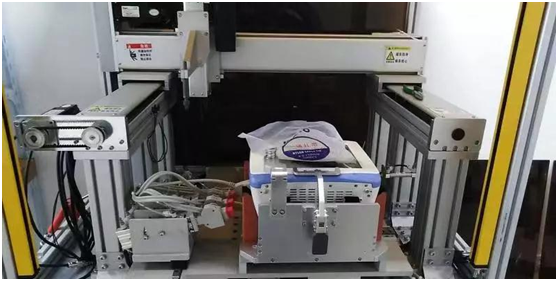

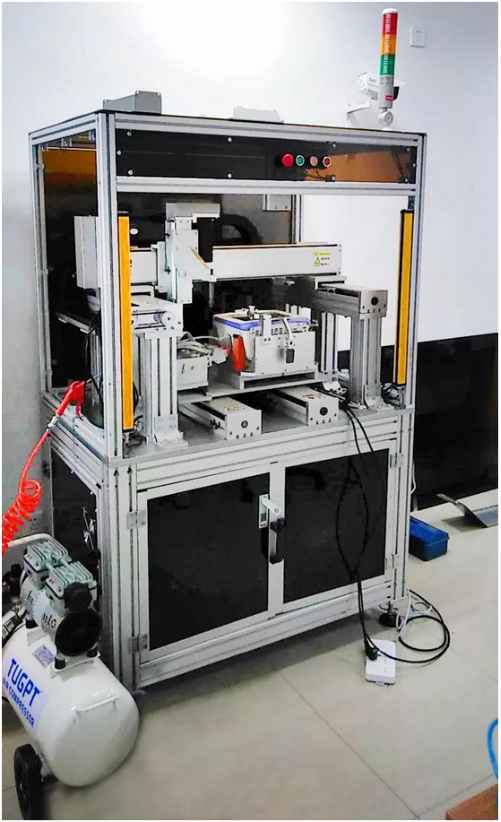

This device is a four-axis module of vision, which adopts a top-class high-end precision camera model XCG-CG510C, equipped with global shutter CMOS sensor, trigger mode, ROI mode and other functions required by machine vision, and can capture high-speed and non-deformed images in motion. With the use of one foreign precision display instrument for product testing and processing, the high speed, priority and intelligence of this visual inspection depend on the stability control of PLC and the quick response and precision execution of servo motor.

For this device, INVT also carefully analyzed the actual manual operability for the operator and added the "reset" button with one button to realize two functions. The inching reset button is used to clear some reset operations with alarm and reset. Long press the reset button for 3 seconds to realize the whole origin regression operation of the module.

After comprehensive consideration, IVC3 PC +DA200 servo motor system solution is adopted by INVT. The TCP-Modbus communication protocol of IVC3 can communicate with the host computer quickly and stably. DA200 high-performance servo system with 2500 line of incremental encoder, the high precision control, 2.0 kHz, high response speed, flexible response, flexible support, strong anti-interference, accurate detection, smaller volume, superior intelligence, improves the visual system of working condition of different artifacts, processes, processing ability and adaptability, perfectly embodies the better performance of high precision testing equipment.

Finally, through the appropriate selection, better hardware configuration and perfect program design, the detection system fully meets the requirements of users and win the customer's affirmation and praise.

1.High detection accuracy, the rate of defective products missing is extremely low.

2.Good stability and environmental adaptability, It has strong anti-interference.

3.Good flexibility, it can achieve varieties of different specifications of product testing, improve the flexibility of production.

4.Greatly improve the production efficiency and the degree of automation of production.

Follow INVT, takes you to experience the magic of machine vision.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev