1. Rich interfaces

Supports 5 types of communication bus protocols.

Supports 4 types of encoder protocols (other encoder protocols are expandable).

2. Powerful functions

Supports various functions including full closed-loop control, load inertia identification, EOE, and positioning compensation.

3. Strong power performance

Designed with 3× overload capacity.

Supports control of multiple motor types including rotary motors, linear motors, and torque motors.

4. Safe and reliable

Supports Safe Torque Off (STO), meeting TÜV SIL3 safety certification.

Supports multiple hardware protections.

Standard equipped with dynamic braking to prevent mechanical damage and ensure personnel safety.

5. Ease of Use

Supports Type-C debugging interface.

Supports one-key parameter auto-tuning, significantly reducing commissioning time.

Simple operation, reducing operational complexity.

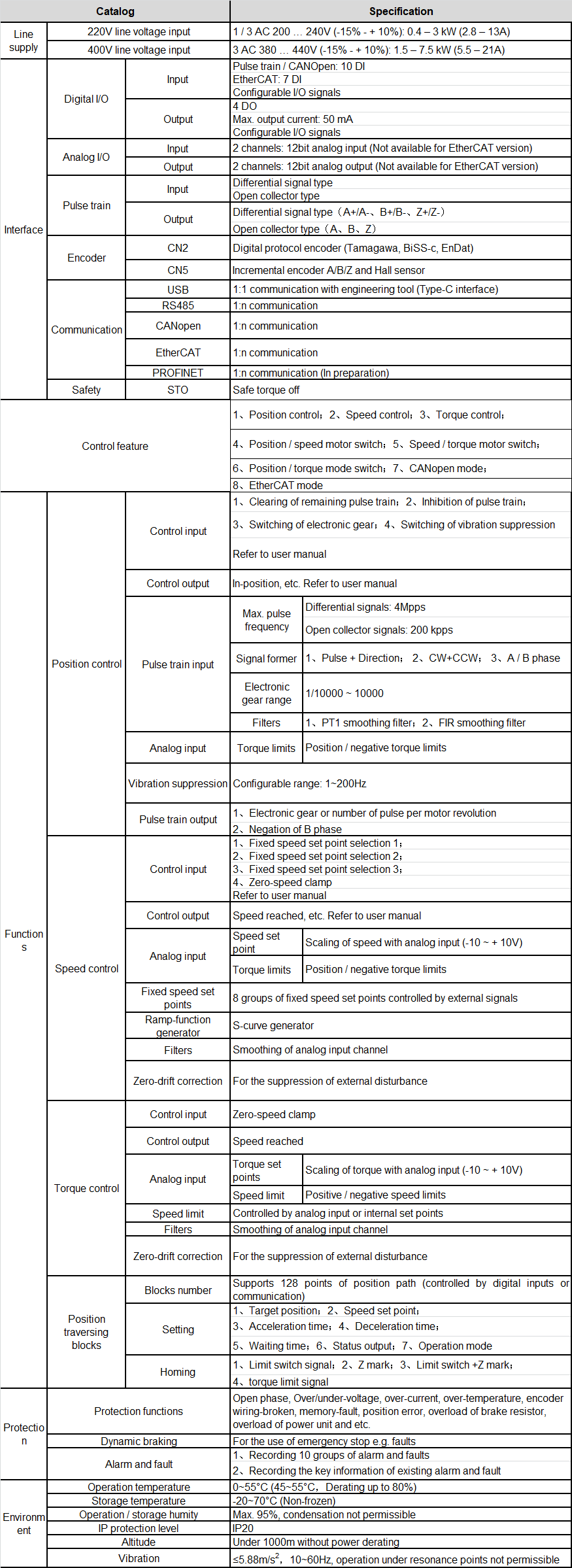

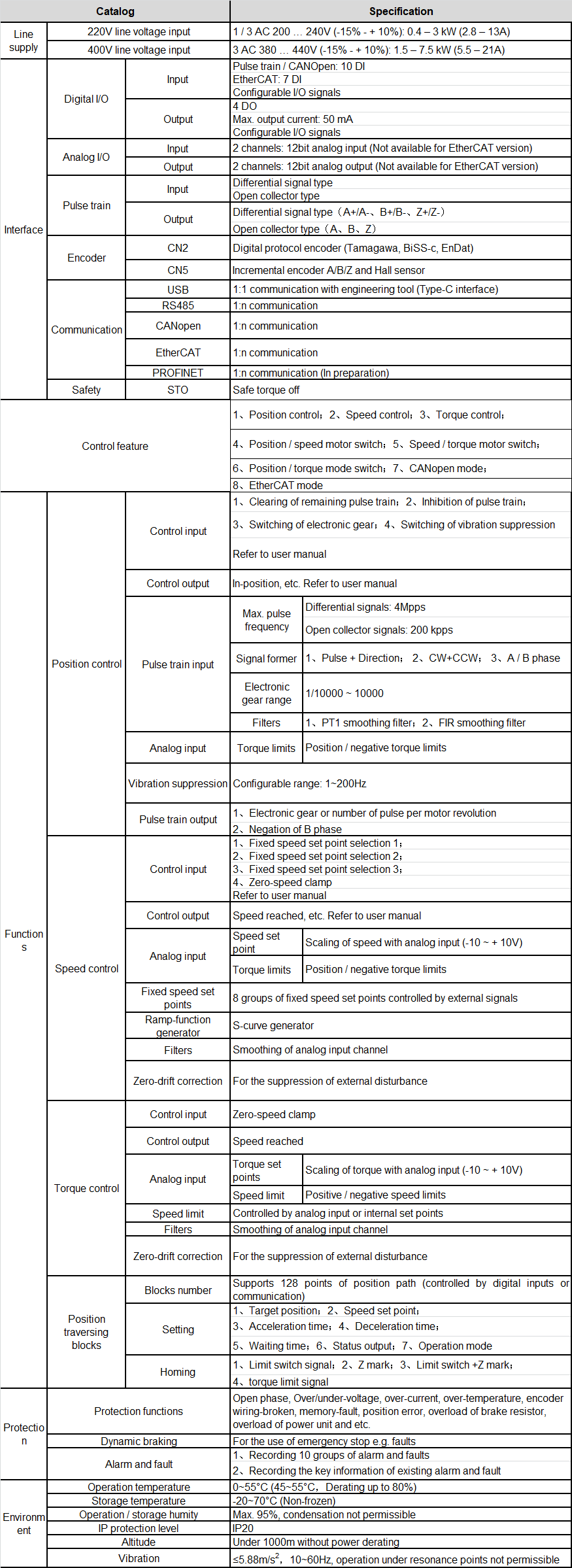

* Specification:

Application of INVT Electro - Hydraulic Servo System in Energy Saving Market of Injection Molding Machine

2020-03-07INVT DA200A Servo for High-speed Solventless Laminating Machine in China

2024-06-04INVT DA200A Servo for Die-cutting Machine Application

2024-10-10INVT DA200A Servo for High-Speed Pick-and-Place Machines

2024-12-27INVT TS600 PLC + DA200A Servo for Dental Floss Packaging Machine Application

2025-01-03INVT Solution for Cut to Length Line in India

2025-04-22

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.