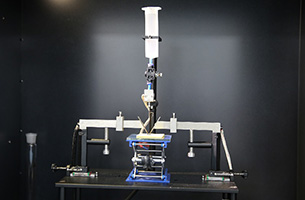

The previous article introduces the sweeping-frequency vibration test in the reliability test, and this article will introduce the mechanical shock test. There is generally a special shock test bench for mechanical shock, but the existing electromagnetic vibration shaker is also completely competent. The shock test is mainly used to expose mechanical weakness or cumulative damage and degradation caused by performance degradation and shock.

Test spectral lines: Different from spectral lines of the sweeping-frequency vibration and random vibration, shock spectral lines mainly reflect acceleration and time physical quantity. The vertical coordinate shows the peak acceleration, which is usually much higher than that of frequency sweeping and random vibration. The common acceleration is 5g, 10g, 15g, 30g, and 50g. The horizontal coordinate is pulse time. The test is transient, and its waveform duration is generally 6ms and 11ms. In addition, the severity mainly includes the shock direction and shock times, and the shock direction is positive and negative directions of three axial directions, and the shock times are more than 3 times per direction.

Test standard: The existing electronics industry mainly involves in GB/T 2423.5-2019, IEC 60068-2-7, etc.

Pulse waveform: It can be divided into half-sine wave, final peak sawtooth wave, and trapezoidal wave.

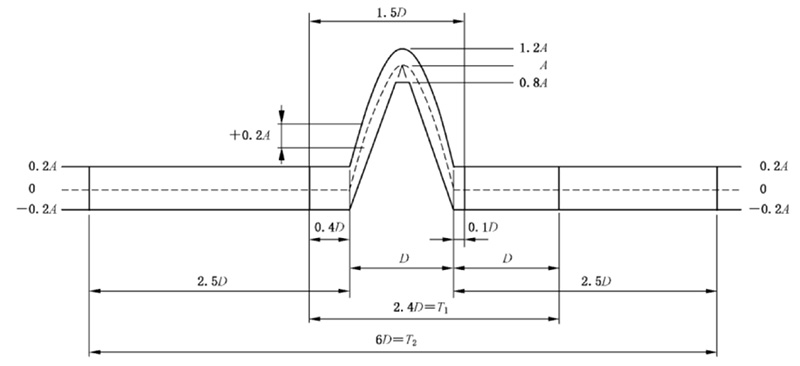

Half-sine wave: It is the half period of a sine wave, as shown in the following figure, which is the most commonly used shock wave.

Final peak sawtooth wave: It is an asymmetric triangle with a short falling time.

Trapezoidal wave: It is a symmetrical trapezoid with a short rising and falling time.

Notes:

D: The duration of the nominal pulse;

A: The peak acceleration of the nominal pulse;

T2: The shortest time to monitor the pulse when the shock is produced by the electrodynamic vibration test bench.

Benefits to product improvement:

1. Installation strength guarantee: The existing low-voltage variable-frequency drives (VFDs) are mainly wall-mounted, and the long-term wall mounting tests the reliability of the wall-mounting hole of the product. Through conducting the random vibration fatigue test and mechanical shock test, we can quickly check whether the strength of the wall-mounting hole reaches the standard.

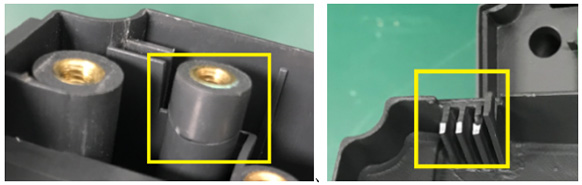

The following picture shows an unreinforced prototype, from which we can know that the wall-mounting hole and its nearby metal plate are obviously cracked. If it is used in a relatively severe environment for a long time, some risks remain.

2. Plastic hook strength guarantee: The low-power VFDs mainly use plastic buckles for structural connection. If the buckle is too hard, it is easy to break while if it is too soft, it is easy to bend and cannot fit each structure well. Through conducting the thermal shock test and mechanical shock test, we can quickly judge whether the brittleness or toughness of the material meets the requirements, and timely adjust the raw materials.

The following picture shows that fracture occurs to the material with low toughness, which will bring the risk of buckle fracture in the disassembly, assembly, and use of the prototype.

3. Rationality guarantee of fixing heavy-duty devices: Transformers, reactors and other devices that affect the center of gravity of the prototype need to be close to the fixed point of the wall mounting, and it is necessary to ensure that the center of gravity of the prototype does not deviate too much to avoid uneven force.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev